Flexible packaging isn’t just a wrapper—it’s a shield. Whether it’s keeping snacks crunchy, coffee aromatic, or medicine effective, the real hero is its barrier properties. These determine how well a pouch or bag fends off threats like air and water. With demands for longer shelf life and smarter materials on the rise, understanding this science can help anyone—from businesses to curious users—make sense of what keeps products fresh. So, how do these barriers work, and why do they matter? Let’s break it down.

What Are Barrier Properties?

Barrier properties measure how well packaging stops external elements—oxygen, moisture, light, or odors—from getting in, while also keeping things like flavor or aroma from escaping. Flexible packaging, made from thin, bendy films like plastic or foil, uses these properties to protect what’s inside. It’s about finding the right level of defense—enough to preserve quality without overcomplicating the design.

The Threats to Your Product

Different products face different enemies:

- Oxygen: Spoils fats, fades colors, and dulls flavors—think coffee losing its punch.

- Moisture: Turns dry goods soggy or clumps powders—crackers hate it.

- Light: Degrades nutrients and dyes—vitamins in a clear bag won’t last.

- Aromas: Lets scents leak out or mix in—nobody wants garlic-tinged candy.

Each threat needs a tailored barrier, and that’s where the materials come in.

The Science Behind the Shield

Barrier performance hinges on permeability—how easily gases or liquids sneak through. Two key metrics tell the story:

- Oxygen Transmission Rate (OTR): Measured in cc/m²/day, it shows oxygen leakage. Lower numbers mean better protection.

- Water Vapor Transmission Rate (WVTR): In g/m²/day, it tracks moisture. A tight barrier keeps this near zero.

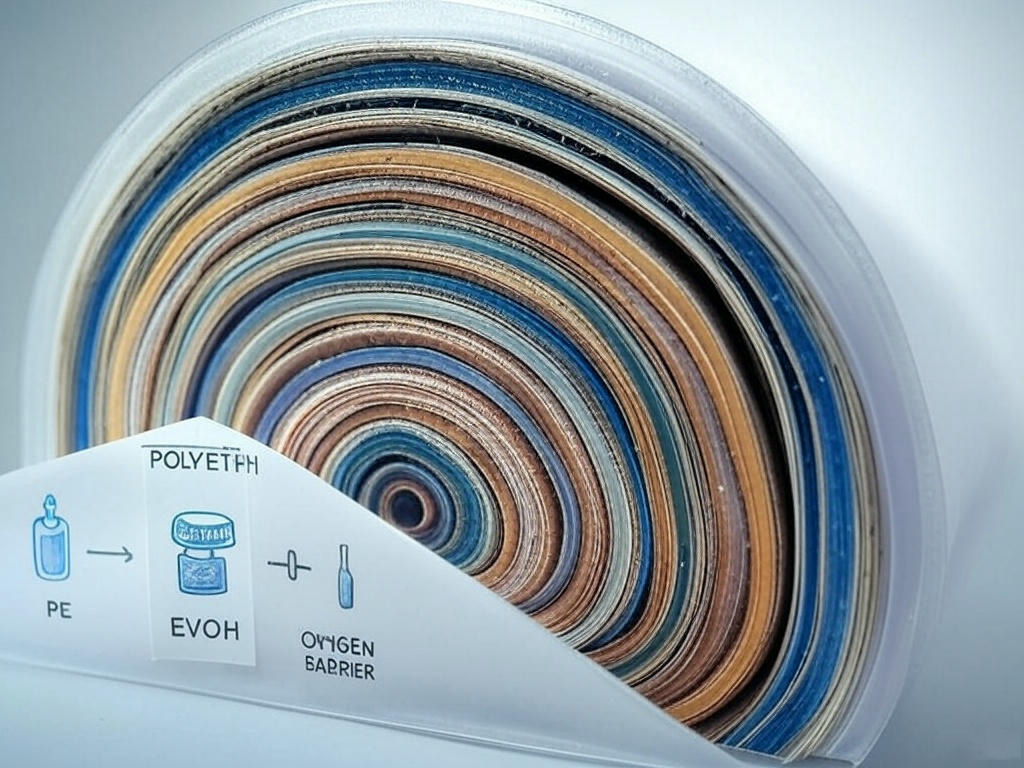

Most flexible packaging stacks multiple layers to tackle these threats. A basic polyethylene (PE) film might stop water but let oxygen through. Add a layer like EVOH (ethylene vinyl alcohol), and oxygen’s locked out. Toss in foil, and light’s blocked too. This layering—through coextrusion or lamination—builds a custom defense.

Materials That Make It Happen

Here’s a rundown of common barrier materials:

- Polyethylene (PE): Good against water, weaker on oxygen—fine for liquids like shampoo.

- EVOH: A top oxygen blocker, often sandwiched between PE layers—great for meats or cheese. It falters if wet, though.

- PVDC: Handles both moisture and oxygen—common in snack bags or blister packs.

- Aluminum Foil: Blocks everything—ideal for sensitive stuff like drugs or coffee, but heavier.

- Metallized Films: Thin metal coatings on plastic—lighter, decent barriers for chips or candy.

Mixing these depends on what you’re protecting—coffee needs foil’s full shield; snacks might just need PVDC.

Putting It to Work

Barrier properties solve real problems:

- Coffee: Without an oxygen barrier, ground beans lose flavor fast—foil or EVOH keeps them fresh.

- Snacks: Moisture ruins crispness—metallized films or PVDC keep the crunch.

- Medicine: Light and air degrade pills—multi-layer sachets preserve potency.

Testing the Barrier

How do you know it’s working? Labs use tools to check OTR and WVTR—standards like ASTM F1927 for oxygen or D3985 for moisture set the bar. A coffee pouch might target an OTR below 2 cc/m²/day; a dry snack bag aims for a WVTR under 1 g/m²/day. These numbers guide material choices to match the product’s needs.

Barriers and the Environment

Great barriers often mean complex films—PE, EVOH, and foil together don’t recycle easily. Single-material options (like all-PE with additives) or bio-based films (like PLA) are emerging, though their barriers aren’t as strong yet. It’s a trade-off—protection versus planet. Knowing this helps you pick what fits your priorities.

Why It’s Worth Understanding

Getting barriers right affects:

- Shelf Life: A strong barrier can stretch freshness from weeks to months—huge for shipping or storage.

- Cost: Too much barrier (foil for a quick snack) wastes money; too little spoils goods.

- Quality: A soggy chip or flat coffee disappoints—barriers keep customers happy.

Think about your product—what’s its biggest threat? That’s your starting point.

The Trade-Offs

High barriers aren’t flawless. Materials like EVOH or foil cost more and add weight. Multi-layer designs complicate recycling—a hot issue with tighter rules in places like the EU. And some barriers need specific conditions—EVOH hates humidity. It’s about balance, not perfection.

Barriers Matter More Than You Think

Barrier properties are the quiet force in flexible packaging—stopping oxygen, trapping moisture, and saving quality. They’re not just tech—they’re choices that shape shelf life, cost, and sustainability. Whether you’re packing snacks or pills, understanding this science helps you protect what matters. Got a product that needs a barrier boost? Start with its enemies—oxygen, water, light—and build from there. What’s your packaging protecting today?