The right packaging design, supplier, and production process can make or break your brand’s success. Whether you’re launching a new business or steering an established one, you understand the value of delivering a standout product wrapped in top-notch packaging. Equally critical is partnering with a supplier who can provide fast, precise, and cost-effective results. The challenge lies in finding a flexible packaging partner that harnesses cutting-edge technology to produce high-quality outcomes tailored to your needs. So, when it comes to printing technology, which option is best for you? Should you stick with conventional printing or explore the possibilities of digital printing? We’ll dive into the differences between these two methods, how they work, and when one might outshine the other—helping you decide whether to switch, upgrade, or blend both into your production strategy.

What’s the Difference?

Let’s start with the basics. Digital printing is the modern kid on the block. It’s like using your home printer, but way fancier. You send a design straight from a computer to the machine, and it uses tiny drops of ink or toner to put your picture or words onto paper. It’s quick and straightforward, with no extra steps to slow you down.

Conventional printing, though, is the old-school way—often called offset printing. It’s more hands-on: you make metal plates with your design, then use those plates to press ink onto paper through a series of rollers. Picture it like a giant stamp at work. It’s been around forever and still powers a lot of big printing jobs today.

Both can give you awesome results, but they’re built for different vibes. Let’s break it down.

Speed: How Fast Can You Get It?

Digital printing wins hands-down for speed on small jobs. Since there’s no setup—like making plates or fiddling with machines—you can go from a file on your screen to a printed page in minutes. Need a few posters for a class event tomorrow? Digital’s your friend.

Conventional printing takes longer to kick off. Crafting those plates and getting the press ready might take hours, sometimes a whole day. But once it’s rolling, it can spit out thousands of copies crazy fast. So, if you’re printing a giant pile of books, that slow start pays off later.

Cost: What’s Easier on Your Wallet?

Money matters, right? For small batches—say, 10 handouts or 50 invites—digital printing is usually the cheaper pick. You don’t have to shell out for plates or setup, just the paper and ink. Perfect for a tight budget or a one-off project.

But if you’re going big, conventional printing starts to look better. The upfront costs are steep because of the plates and prep, but once you’re printing thousands, the price per copy drops way down. Imagine printing a school yearbook run of 5,000—conventional could save you some serious cash.

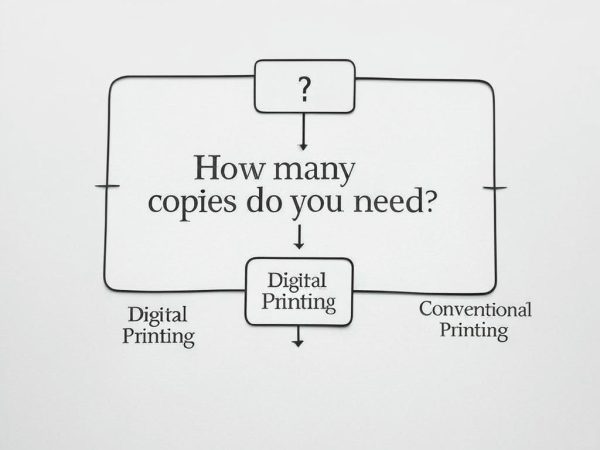

It’s all about how much you need. A little? Digital’s got you. A lot? Conventional’s the smarter bet.

Quality: Which Looks Nicer?

What about the final product? Digital printing has come a long way—it’s sharp, colorful, and handles details like a champ. Whether it’s a photo of your dog or a bright drawing, it’ll pop off the page just fine.

Conventional printing, though, has a reputation for being top-tier, especially on big jobs. It nails those smooth color fades you see in slick ads and keeps everything looking consistent, even after thousands of copies. That’s why pros use it for stuff like magazines or fancy packaging.

Truth is, unless you’re super picky, both can look great. For most things—like a school poster—you probably won’t spot much difference.

Flexibility: Can You Mix It Up?

Here’s where digital printing flexes its muscles. No plates mean you can tweak things on the fly. Want 10 flyers, each with a different name? Digital makes it a breeze. It’s awesome for personal touches, like custom party invites.

Conventional printing isn’t as nimble. Once those plates are done, changing anything means starting over—more time, more cost. It’s best when you’re locked into one design, like a pile of identical handouts.

What About the Planet?

Eco-friendliness counts too. Digital printing tends to be lighter on waste for small runs—no extra paper or ink gets tossed, and the machines often sip less power. Conventional printing uses chemicals for plates and guzzles more energy, though it can even out when you’re printing massive batches.

So, Which Wins?

There’s no clear champ here—it’s all about what you need. Digital printing’s your go-to for quick, small, affordable jobs with some wiggle room for changes. Conventional shines when you’re cranking out thousands of copies and want every single one to look flawless at a lower per-page cost.

Wrapping It Up

So, is digital printing better than conventional? It depends on your project. Both are awesome in their own way, and it’s cool we’ve got choices. Next time you’re printing something—maybe a sketch for art class or a stack of club flyers—think about how many you need, how fast you want them, and what you’re willing to spend. That’ll steer you right.