Choosing the right materials for custom packing is crucial for ensuring that your product is protected, visually appealing, and aligned with your brand’s sustainability goals. From food and beverages to electronics and cosmetics, every industry has specific needs when it comes to packaging. In this article, we will explore the factors to consider when choosing materials for your custom packing needs and how to make the right decision.

1. Understand the Product’s Nature

The first and most important factor when selecting materials for custom packing is understanding your product’s specific needs. For instance, food packaging requires materials that preserve freshness and protect against moisture, while electronics require anti-static protection. Here are a few common product categories and their requirements:

- Food Products: Look for materials that offer airtight seals and moisture resistance, such as flexible packaging films or vacuum-sealed pouches.

- Cosmetics: Choose packaging that is leak-proof and protects against contamination, often requiring materials like laminated plastics or glass.

- Electronics: Opt for materials that prevent static build-up, such as anti-static plastic or foam linings.

Understanding your product’s characteristics will guide you in selecting the right packing material.

2. Consider the Packaging’s Functionality

The functionality of your packaging plays a critical role in material selection. Ask yourself what purpose the packaging must serve beyond just containing the product. Does it need to be resealable? Does it require additional protection during transportation? For example:

- Durability: Choose materials that can withstand rough handling if your product is shipped over long distances. Corrugated cardboard or heavy-duty plastic can offer excellent protection.

- Resealability: For products like snacks or cosmetics, resealable zippers or closures are essential to keep the product fresh after opening.

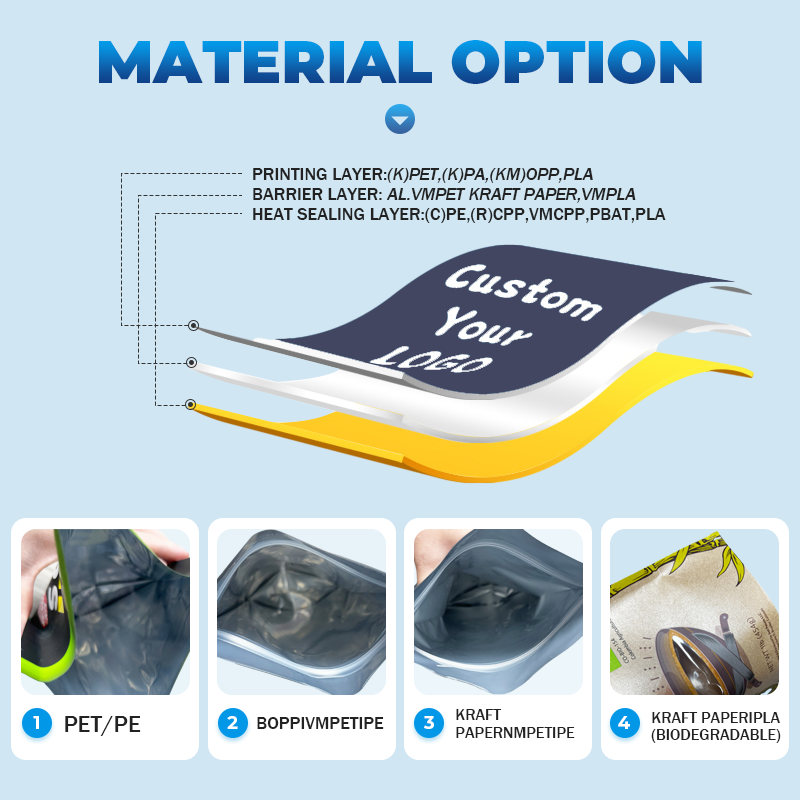

- Barrier Protection: Some products need protection from external elements such as light, oxygen, or moisture. Flexible films with aluminum foil layers are often used for this purpose.

3. Aesthetic Appeal and Branding

Packaging is not only about protection—it’s also a key part of your marketing strategy. Custom packing can significantly influence your brand’s visibility and appeal. Here are factors to consider from an aesthetic point of view:

- Material Finish: Matte, glossy, or textured finishes can impact how the product is perceived on the shelf.

- Printability: Choose materials that allow for high-quality printing to showcase your brand’s design, logo, and product information effectively. Laminated materials are often a good option for vibrant prints.

- Transparency: Some products, such as food items, benefit from clear packaging that lets customers see the product directly.

4. Sustainability and Environmental Considerations

In today’s market, consumers are increasingly concerned about environmental impact. Choosing eco-friendly materials for custom packing can enhance your brand’s image and appeal to eco-conscious customers. Here are a few sustainable options:

- Recyclable Materials: Opt for materials that can be recycled easily, such as PET plastic, cardboard, or aluminum.

- Biodegradable and Compostable Materials: Materials like PLA (polylactic acid) are compostable, making them a good option for brands looking to reduce environmental impact.

- Reduced Material Usage: You can also minimize the environmental footprint by using thinner, lightweight materials that still offer adequate protection for your product.

5. Cost-Effectiveness

Finally, it’s essential to balance quality with cost-effectiveness. Choosing high-end materials may increase your packaging costs, but they could also lead to increased customer satisfaction and repeat sales. On the other hand, cheaper materials may save on upfront costs but could compromise the quality of your product’s presentation or protection.

One cost-effective solution is to work with a packaging supplier who offers a wide range of material options. This allows you to choose the best materials within your budget without compromising on quality.

Conclusion

Selecting the right materials for custom packing is a critical decision that impacts both your product’s safety and your brand’s success. Whether you prioritize sustainability, durability, or visual appeal, finding the right balance is key. At Colorful Packaging, we specialize in providing high-quality, customizable packing solutions that cater to various industries. Our extensive material options and design capabilities ensure that your product stands out while meeting all your packaging requirements. Learn more about how we can help by visiting our website at Colorful Packaging.