Multilayer soft packaging is a marvel of modern design—think of the shiny coffee pouch keeping your beans fresh or the sturdy bag holding your frozen veggies. These aren’t just single sheets of plastic; they’re carefully built stacks of materials working together to protect, preserve, and perform. But what makes an “ideal” structure for multilayer soft packaging? It’s not a one-size-fits-all answer—it depends on balancing protection, practicality, and production realities. Let’s peel back the layers and explore what goes into crafting the perfect setup.

Why Multilayer Matters

First off, why bother with multiple layers? A single sheet of plastic might work for a basic bag, but today’s products—food, medicine, or industrial goods—demand more. One layer can’t do it all: block oxygen, hold up to rough handling, and look good on the shelf. Multilayer soft packaging solves this by combining materials, each with its own strengths, into a single, flexible film. The trick is figuring out how to stack them to get the best results without overcomplicating things.

The ideal structure isn’t about piling on as many layers as possible—it’s about picking the right ones for the job and making them play nice together. Whether it’s keeping potato chips crunchy or ensuring a medical device stays sterile, the structure has to match the product’s needs.

The Core Building Blocks

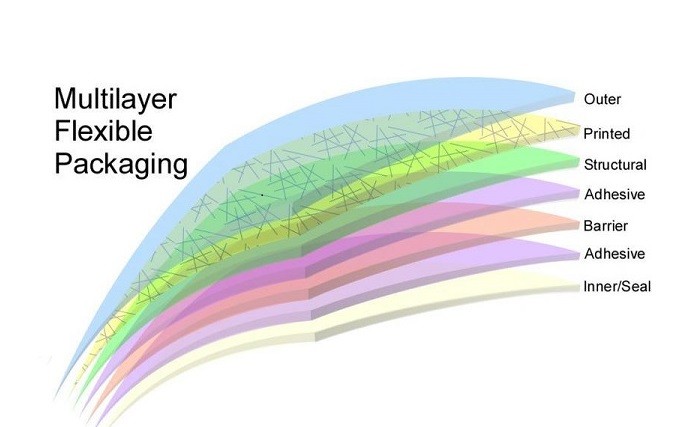

So, what goes into this ideal setup? Most multilayer soft packaging follows a basic blueprint, with layers tailored to specific roles:

- Outer Layer: This is the face of the package—tough, printable, and often the first line of defense. Polyester (PET) is a popular choice here because it’s strong, resists scratches, and takes ink well for sharp branding. It’s what you see and feel, so it’s got to stand up to wear and tear.

- Barrier Layer: The guardian of freshness, this layer blocks oxygen, moisture, or light. Aluminum foil shines here—literally—for things like coffee or pharmaceuticals, where even a hint of air can spoil the contents. For less demanding needs, materials like EVOH (ethylene vinyl alcohol) step in, offering solid oxygen resistance without the metallic heft.

- Inner Layer: This one’s in direct contact with the product, so it has to seal well and play safe. Polyethylene (PE) often takes this spot—it’s flexible, melts easily for heat sealing, and doesn’t mess with food or medicine. It’s the layer that locks everything in tight.

- Tie Layers: These unsung heroes glue it all together. Different materials—like PET and PE—don’t naturally bond, so adhesive resins or co-extruded tie layers bridge the gap, keeping the stack intact.

A classic example? A snack bag might start with PET on the outside for durability and print, add a thin foil or EVOH for barrier power, and finish with PE inside for sealing. Three or four layers, each doing its part.

Tailoring to the Task

The “ideal” structure shifts depending on what’s inside. Take food packaging: a bag of dried fruit needs moisture protection, so a strong water-vapor barrier like foil or high-density PE might lead the charge. Frozen goods, on the other hand, lean on toughness—thicker PE or PP layers to handle subzero brittleness without cracking. For microwaveable meals, polypropylene steps up since it can take the heat without melting into a puddle.

Pharmaceuticals bring their own rules. Sterility is king, so the inner layer might double down on chemical inertness, while an outer foil layer blocks light and air to protect sensitive drugs. Industrial products, like chemical powders, might prioritize puncture resistance with extra nylon or thicker films. The point is, there’s no universal perfect stack—it’s about matching the layers to the mission.

Balancing Performance and Practicality

Building the ideal structure isn’t just about performance—it’s also about keeping things doable. More layers can mean better protection, but they also jack up costs and complicate production. A seven-layer film might sound impressive, but if it’s overkill for a simple candy wrapper, you’re wasting money. The sweet spot is usually three to five layers—enough to cover the bases without bogging down the process.

Weight matters too. A lightweight structure cuts shipping costs and feels eco-friendlier, but skimp too much, and you risk a flimsy package that tears open in transit. Heat sealing adds another wrinkle: the inner layer has to melt just right, and too many mismatched layers can throw that off. The ideal setup finds harmony—strong enough to work, lean enough to make sense.

Real-World Challenges

Even a well-designed structure faces hurdles. One big one? Layer compatibility. If the outer PET and inner PE don’t bond smoothly, you get delamination—where the layers peel apart like a bad sandwich. Tie layers help, but they add complexity. Another issue is recycling: multilayer films, with their mix of plastics and foils, are tough to break down. The ideal structure today might lean toward “mono-materials”—all-PE stacks, for instance—to ease that burden, though they sacrifice some barrier power.

Production quirks play a role too. Co-extrusion—where layers are melted and fused in one go—can streamline things, but it demands precise equipment. Laminating separate layers offers flexibility but slows the pace. The ideal design doesn’t just perform; it fits the factory’s reality.

A Peek at the Future

What’s “ideal” keeps evolving. Sustainability is pushing single-material designs, like all-polyethylene films, to cut recycling headaches—though they’re still catching up on barrier strength. Bio-based layers, like PLA (polylactic acid), are creeping in for eco-appeal, but they’re trickier to seal and less durable. Smart packaging is another twist—adding sensor layers to track freshness—though it’s still niche. The best structures tomorrow will juggle these trends with the old standbys of protection and cost.

Putting It All Together

So, what makes the ideal multilayer soft packaging structure? It’s a team effort—layers like PET, foil, and PE each bringing something to the table, tuned to the product’s needs and the real world’s demands. It’s tough yet light, protective yet practical, and built to seal tight without breaking the bank. A coffee pouch might nail it with three layers; a medical pack might need five. There’s no magic formula—just a smart balance of purpose and possibility. That’s the beauty of multilayer design: it’s less about perfection and more about getting it just right for the job at hand.