Flexible packaging products are revolutionizing the packaging industry by offering innovative solutions that meet the needs of various sectors, from food and beverage to pharmaceuticals and consumer goods. These products are made from flexible materials, allowing them to be easily bent, folded, or conformed to the shape of the product inside. This blog post will explore the characteristics, advantages, applications, and sustainability of flexible packaging, providing a comprehensive overview for businesses considering this packaging solution.

Characteristics of Flexible Packaging

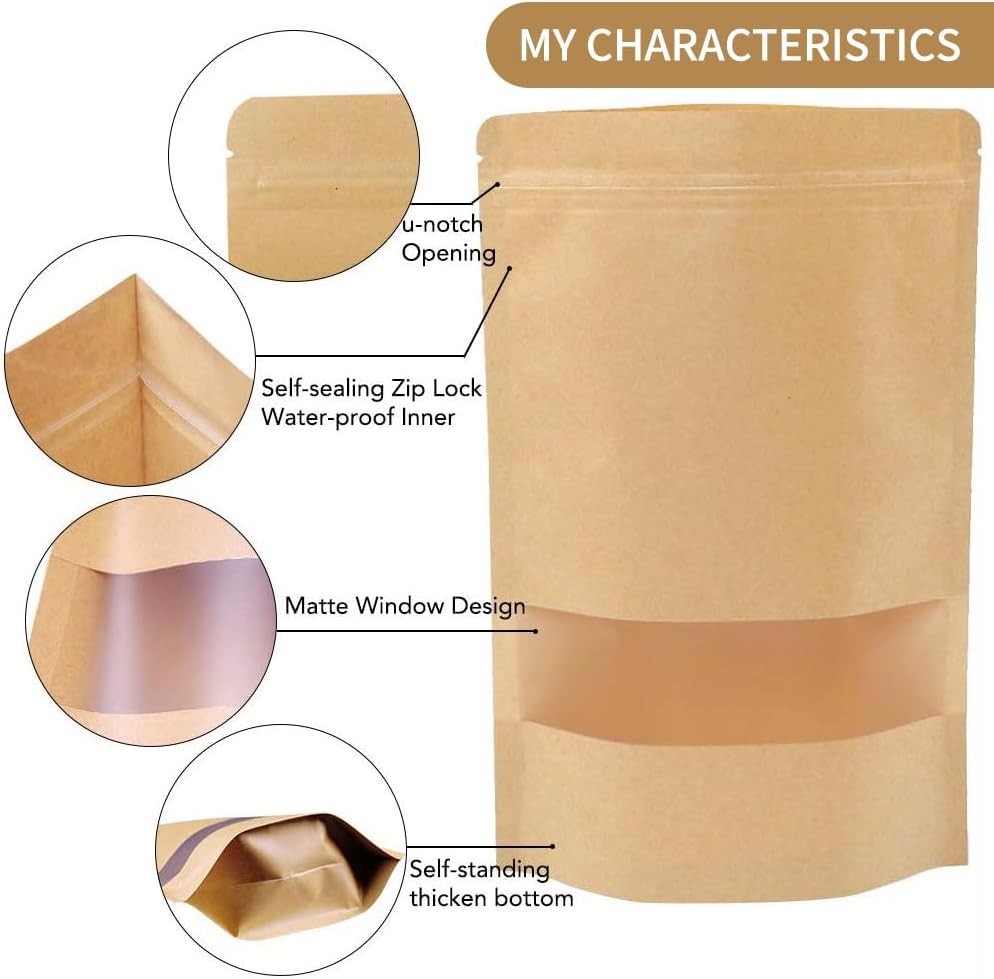

Flexible packaging encompasses a wide range of materials, including plastic films, paper, aluminum foils, and multi-layer laminates. These materials can be tailored to create packaging that meets specific requirements for protection, shelf life, and branding. Here are some key characteristics of flexible packaging:

- Material Versatility: Flexible packaging can be constructed from various materials, allowing manufacturers to choose the best combination for their products. This versatility makes it suitable for a broad range of applications.

- Barrier Properties: Many flexible packaging solutions are designed with excellent barrier properties, protecting products from moisture, light, oxygen, and contaminants. This feature is essential for maintaining product quality and freshness, especially in the food and beverage sector.

- Customizability: Flexible packaging can be easily customized in terms of size, shape, and design. Brands can create unique packaging that enhances their product’s visual appeal and aligns with their marketing strategy.

- Lightweight: One of the most significant advantages of flexible packaging is its lightweight nature. This characteristic not only reduces transportation costs but also lessens the overall environmental impact.

Advantages of Flexible Packaging

The growing popularity of flexible packaging products can be attributed to their numerous advantages:

- Cost-Effectiveness: Flexible packaging often requires fewer materials and less energy to produce compared to rigid packaging. This efficiency translates into lower costs for manufacturers and consumers.

- Extended Shelf Life: By providing a strong barrier against external factors, flexible packaging can significantly extend the shelf life of products. This feature is particularly beneficial for perishable items, as it helps reduce food waste.

- Space Efficiency: Flexible packages can be flattened or rolled when not in use, making them space-efficient for storage and transportation. This characteristic is especially valuable for businesses looking to optimize their logistics.

- Consumer Convenience: Many flexible packaging options come with features such as resealable closures, spouts, or easy-tear openings. These enhancements improve the user experience, making products more appealing to consumers.

- Branding Opportunities: Flexible packaging allows for high-quality graphics and branding, enabling brands to effectively communicate their message and stand out on the shelves. The ability to print directly on the packaging increases visibility and attractiveness.

Applications of Flexible Packaging

Flexible packaging products are utilized across a wide range of industries, demonstrating their versatility and adaptability. Here are some common applications:

- Food and Beverage: Flexible packaging is widely used for snacks, frozen foods, beverages, and ready-to-eat meals. Its barrier properties help preserve freshness and extend shelf life, making it a popular choice for food manufacturers.

- Pharmaceuticals: In the pharmaceutical industry, flexible packaging is used for a variety of products, including tablets, powders, and liquid medications. The ability to create tamper-evident and child-resistant packaging enhances safety and compliance.

- Personal Care Products: Flexible packaging is also commonly used for personal care items such as lotions, shampoos, and wipes. The customizable designs and convenient features cater to consumer preferences.

- Household Goods: Flexible packaging is suitable for cleaning products, pet food, and other household items. Its lightweight and space-efficient nature makes it ideal for both manufacturers and consumers.

Sustainability in Flexible Packaging

As environmental concerns continue to grow, the flexible packaging industry is taking significant steps toward sustainability. Many flexible packaging products are now designed with eco-friendly materials, including recyclable and biodegradable options. Here are some key points regarding sustainability in flexible packaging:

- Recyclability: Advances in technology have led to the development of flexible packaging that can be recycled. Brands are increasingly adopting materials that can be processed in existing recycling streams.

- Biodegradable Options: Some manufacturers are producing flexible packaging from biodegradable materials, allowing for a reduced environmental impact when the packaging is disposed of.

- Reduced Carbon Footprint: The lightweight nature of flexible packaging contributes to a smaller carbon footprint during transportation. Additionally, efficient production processes help minimize energy consumption.

- Consumer Awareness: As consumers become more environmentally conscious, they are actively seeking products that utilize sustainable packaging. Brands that embrace eco-friendly practices can enhance their market appeal.

Conclusion

Flexible packaging products are transforming the packaging landscape with their versatility, cost-effectiveness, and sustainability. By offering a range of advantages, including extended shelf life and customization options, flexible packaging is an ideal choice for various industries. As brands increasingly prioritize eco-friendly practices, flexible packaging will continue to play a vital role in meeting consumer demands and reducing environmental impact.